Generations of craftsmanship within reach

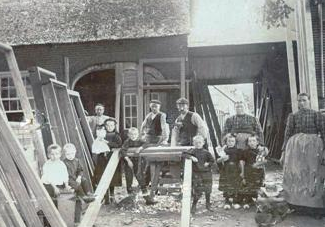

Knowledge of woodworking, technology and software come together in every ØDE table. The proven craftsmanship is due to a Udenhout family business with a history dating back to 1754.

Carpentry factory J. van de Plas is the place where every ØDE table is produced with great care, from start to end product. The Carpentry company from Udenhout is well-known in the region, but is also nationally renowned for high-quality woodworking and restorations.

Co-founder and director of craftmanship at ØDE, Rolf van de Plas is managing this company and shares his story.

Anno 2022, co-founder and director of craftmanship at ØDE, Rolf van de Plas has been managing the carpentry factory for eighteen years – as the eighth consecutive generation. Rolf has now prepared the company for the future with a strong combination of traditional craftsmanship and modern techniques.

In the picture: Co-founder and Director of Craftmanship at ØDE, Rolf van de Plas and his father Jeff van de Plas. Photography: Marjolein Ansink.

As the twig is bent the tree is inclined

ánd vice versa.

It was not as obvious that Rolf took over from his father as with his predecessors. With a background as a marketer, it took him a bit longer before he finally decided to take over the family business. In 2005 the time was right. With a total of three craftsmen and a handful of devices, each restoration job was carried out to perfection.

The expertise of these people was – and still is – worth gold as far as Rolf is concerned: “The machines from our old workshop are still standing on the floor and the new team can also handle them well. Extremely valuable knowledge that they have gained from the older generation of professionals.”

Turning things around

with modernization.

The time of working with classic woodworking equipment and instruments is certainly not over as far as Rolf is concerned: “With, among other things, a tenoning bench, chain cutter, circular saw and some other classic tools, our employees can handle the most laborious tasks. This includes the restoration of exclusive historic or monumental buildings, churches and castles. As long as it concerns wood, we know what to do with it.”

However, a modernization effort was inevitable. In the middle of the crisis, in 2012, Rolf expanded the machine park with a CNC machine. CNC stands for computer numerical control – an advanced computer-controlled machine. In the meantime, there are three CNC machines in total, which allowed the entire production process to be automated even further.

At Van de Plas there is a lot of knowledge about processing solid wood using CNC technology. “Something that is unique in the Netherlands. These machines are usually equipped for mass production, standard profiling and sheet material. However, we have translated our specific knowledge of traditional connections and materials into our own CNC software. An ambition that did require a lot of effort.”

Thanks to the CNC technology, the aesthetic carpentry is affordable and Van de Plas can also continue to serve private customers who want a beautiful piece of frame in the facade.

Collaboration between

Van de Plas and ØDE.

The CNC technique is not only applied to window frames and other objects mentioned above. The CNC machine is also involved in the production of all designs for ØDE. n his role, Rolf mainly looks at the ØDE tables from a technical point of view and that is actually what makes it special for him.

“With our mastery of both old and modern techniques, we went in search of authentic connections. I am also very pleased with the types of wood we use in the production. It just gives me a thrill every time I look at a table.

That we select the types of wood in our factory that we find suitable for ØDE and that we skillfully combine the necessary techniques on that basis. In the end, manual work is always involved to put the traditional finishing touches.”

New never

replaces old.

The essential handiwork proves all the more that traditional carpentry is a craft built on age-old craftsmanship. That’s why Rolf thinks it’s wonderful that old and new go together so well and even reinforce each other.

It is clear that the carpentry business is ready for the future. May many more generations follow.

Meer weten over de historie van Timmerfabriek J. Van de Plas? Lees hier een artikel dat er uitgebreider op ingaat.